|

MG2 Ultrasonic Thickness Gages

|

These small affordable ultrasonic thickness

gages are primarily designed for inspectors and maintenance engineers

responsible for measuring the remaining thickness of internally

corroded pipes, tanks, and other metal structures.

Lightweight and ergonomically designed for

easy one-hand operation, these gages provide cost-effective

measurement solutions in many applications that require quick

inspection of materials suspected of metal wall thinning.

These thickness gages truly combine

quality, accuracy, and ease of operation at affordable prices.

|

Each gage offers a range of

practical measurement features to solve a wide variety of thickness

gaging problems.

Download pdf Brochure

(520 kb) |

|

MG2

The MG2 offers many basic

features such as Min/Max Mode that measures and recalls the minimum

thickness at a fast 20 readings per second, Freeze Mode to instantly

capture critical thickness, and Zero Compensation to ensure optimal

transducer performance. Various other features make this handheld gage an

affordable unit for quick spot measurements.

|

MG2-XT

The MG2-XT has all of the

features of the MG2 plus much more! Gain Adjust, Auto Sensitivity

Optimizations,

Echo-to-Echo,

Thru-Coat,

Differential Mode, and Hi-Low Alarm are added features to provide you with

more measurement capabilities in tough applications. This gage is ideal

when you make thickness measurements on coated or painted surfaces.

|

MG2-DL

The MG2-DL is the most

advanced unit of our new MG2 Series gages. It includes all of the features

found in the MG2-XT plus a versatile file-based alphanumeric data logger

that employs incremental, sequential, and 2-D grid file formats. The

MG2-DL is the answer if youre looking for an affordable gage with unique

measurement capabilities such as Thru-Coat and Gain Adjust. The optional

GageView Pro

interface program helps manage and format stored inspection

data for high-speed transfer to the PC.

|

MG2

Ultrasonic Thickness Gage Comparison Chart

|

Comparison Chart |

MG2-DL |

MG2-XT |

MG2 |

|

Thickness Range .020"-25.00" (0.50-635.0 mm) |

|

|

|

|

Thickness Display Resolution up to 0.001" (0.01 mm) |

|

|

|

|

Automatic Probe Recognition |

|

|

|

|

High Temperature Capabilities |

|

|

|

|

Fast Measurement Rate of 20 per second |

|

|

|

|

Min/Max Mode |

|

|

|

|

Freeze Mode |

|

|

|

|

Zero Compensation Mode |

|

|

|

|

Display Hold/Blank |

|

|

|

|

Inches/Millimeters Mode |

|

|

|

|

Gain Adjust |

|

|

- |

|

Auto Sensitivity Gain Optimization |

|

|

- |

|

Differential Mode |

|

|

- |

|

Hi-Low Alarm |

|

|

- |

|

Thru Coat |

|

|

- |

|

Echo-to-Echo |

|

|

- |

|

Internal Datalogger |

|

- |

- |

|

GageView Interface Program |

|

- |

- |

|

A. File

Name (2) |

E. Gain

Adjust (1) |

I.

Battery Life |

|

B. Freeze

Mode |

F.

Measurement Rates |

J.

Available Keys |

|

C. Differential Mode (1) |

G. Pervious Thickness (2) |

K. User

Help |

|

D. Hi-Low

Alarm (1) |

H.

Current Measurement |

L. ID#

(2) |

|

(1)

Features provided with the MG2-XT and MG2-DL

(2)

Features provided with the MG2-DL |

|

MEASUREMENTS FROM ONE SIDE!

Ultrasonic thickness gages

make instant digital measurements by transmitting sound into a material

from one side, making it unnecessary to cut the corroded part.

LIGHTWEIGHT AND POCKET-SIZE

These handheld gages are

small enough to fit in a toolbox or inside your pocket. They are ideal for

quick inspections in hard-to-reach areas.

INTUITIVE, COLOR-CODED

KEYPAD

You can directly access

many important measurement features for time-saving operation.

Strategically located keys are grouped together by color for easy

opperation.

|

LARGE LCD WITH BACKLIGHT

The large numerals make it

easy to read thickness measurements. In addition, you can easily view the

electroluminescent backlit display from total darkness to bright sunshine.

BUILT TO LAST!

The splash proof, impact-resistant

case with sealed keypad makes these gages durable tools in the harshest

conditions. All gages offer a Two Year Limited Warranty.

Available with the MG2-DL

and MG2-XT models only.

|

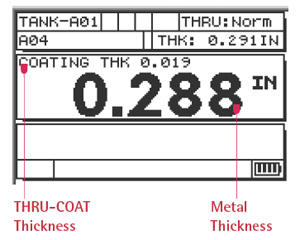

MG2-XT and MG2-DL

are available with

THRU-COATฎ

With this patented

technology, the gage simultaneously displays the thickness of the coating

and the true metal thickness, using a single backwall echo. Each

measurement is adjusted for their calibrated material sound velocity. Thru-Coat

measurements use the D7906-SM and D7908 transducers. This feature will

save you valuable inspection time!

|

ECHO-TO-ECHO

The gage displays the true

metal thickness and ignores the thickness of the coating layer, using

multiple backwall echoes. There is no need to remove the coating.

GAIN ADJUST

This is a feature you can

use when making measurements on sound-attenuating materials such as

cast metals. By adjusting the gain level (High, Low, or Standard) you

can reduce material or surface noise when ultrasound enters rough or

granular surfaces in order to improve the detection of the backwall. |

AUTO SENSITIVITY GAIN OPTIMIZATION

This feature

is similar to Gain Adjust. Instead of you setting the gain level, the

gage automatically increases or decreases the gain depending on the

thickness and material noise level.

DIFFERENTIAL MODE

A differential

measurement references two readings to each other. The gage displays

the difference between the live measurement and a preset reference

thickness.

HI-LOW ALARM

You can

program the gage with Min/Max thickness values. Audable or visual

indicators will warn you of out of tolerance conditions. |

TRANSDUCERS WITH

AUTOMATIC PROBE RECOGNITION

Each MG2 series

gage is compatible with our complete line of easy interchangeable dual

element transducers that vary in frequencies, diameters, and temperature

capabilities to deal with virtually every application.

SPECIFICATIONS

|

MEASUREMENTS

Mesurement

Mode:

Pulse echo with dual

element transducers

Thickness

Measurement Range: 0.020 to 25.00 inch (0.50 to 635.0 mm)

Thickness

range depends on material, transducer, surface condition, temperature

Material

Velocity Calibration Range: 0.0200-0.7362 in/ตsec (0.508- 18.699

mm/ตsec)

Thickness

Display Resolution:

|

LOW: |

0.01" |

0.1 mm |

|

STANDARD: |

0.001" |

0.01 mm |

Measurement

Rates:

Standard Rate:

4 per second

Fast Rate:

20 per second

Min/Max Mode:

Measures and recalls minimum or maximum thickness at 20

measurements per second.

Freeze Mode:

Freezes display to instantly capture critical thickness. Minimizes

transducer couplant lift-off error and facilitates High Temperature

measurements.

Automatic

Probe Recognition: Automatically recognizes the listed Panametrics-NDT

transducer types. Adjusts internal parameters and corrects V-path

error.

Zero

Compensation: Compensates for transducer temperature and zero

offset.

MG2-XT AND MG2-DL ADDITIONAL SPECIFICATIONS

Thru-Coatฎ

Measurement: Measurement of true metal and coating thickness using

a single backwall echo (with D7906-SM and D7908 transducers)

Thru-Paint

Echo-to-Echo: Time interval between two successive backwall echoes

for elimination of paint or coating

Gain Adjust:

Selectable Gain between Standard, Hi and Low.

Auto

Sensitivity Gain Optimization:

Allows the normal measurement

sensitivity to be automatically increased or decreased depending on

the thickness and material noise level.

Alarm Mode:

Programmable Hi-Low set points with audible and visual indicators

Differential

Mode:

Displays the difference between the

actual thickness measurement and a user-set reference value.

Setting up

measurement parameters has never been easier! Using the arrows, you

scroll through the set-up menu and quickly select desired parameters. |

DISPLAY

Display Hold/Blank

Mode: Display holds or blanks

after measurement.

Electroluminescent Display Back Lighting: Selectable as On or

Auto On

Receiver

Bandwidth: 1-18 MHz (-3 dB)

Metric/English

Mode: Metric or English

POWER SUPPLY

Battery:

3 AA alkaline batteries

Operating Time:

150 hours typical battery life, 30 hours continuous with backlight

on.

Low Battery

Indicator: Continuously

indicates battery status.

Battery Saver:

Auto Power Off/Continuous On.

GENERAL

Case/Keypad:

Splash proof, impact-resistant

case. Sealed, color coded keypad with tactile and audible feedback

Operating

Temperature Range: -10ฐC to +50ฐC, +14ฐF to 122ฐF.

Size:

3.31

W x 6.0 L x 1.56 H (84 x 152.4 x 39.6 mm)

Weight: 12

oz. (0.34 kg)

Hazardous Area

Operations: As defined by MIL-STD-810E, method 511.3, procedure 1.

MG2-DL INTERNAL DATALOGGER

Datalogger:

The MG2-DL will identify,

store, recall, clear, and transmit thickness readings and gage setup

information via the USB Port.

Max. # of

Stored Values: Over 8,000 thickness readings

Stored Data

Documentation:

Each saved thickness reading is fully

documented with measurement status flags and a setup number that

identifies parameters such as velocity, transducer, etc.

File Name

Length:

8 alphanumeric characters

Identification

Codes:

10 character alphanumeric Identification

Code system identifies or locates stored data.

3 File

Templates: Incremental, sequental and 2D Grid

STANDARD INCLUSIONS

Model MG2

Digital Ultrasonic Thickness Gage, Wrist Strap, Test Bar, Couplant,

Instruction Manual and a Two Year Limited Warranty. Standard packages

include a dual element transducer.

OPTIONAL ACCESSORIES

2214E

5-Step Test Block, English units

2214M

5-Step Test Block, Metric units

MG/EW

Extended Warranty |

|