|

Automated Ultrasonic (UT)

Weld and Flaw Inspection

The automated ultrasonic (UT) system provide high speed accurate

measurements for weld / flaw detection. The instruments are

fully programmable / configurable to provide high resolution C-Scans

of weld seams for a large number of different structure geometries.

The instruments perform inspections quickly (about 0.5m/min

linear scanning velocity), with resolution, in this case, of 1.25

[transverse to weld] x 6 mm. The results are available in real-time,

and consist of color-coded amplitude "maps" corresponding

to the severity of the indications found. Location (depth) of

defects can be determined using time-of-flight data, which is

also recorded along with the amplitude data.

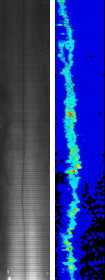

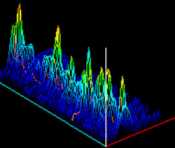

As shown on the accompanying figures, the ultrasonic data, which

is available as either 2-D or 3-D C-Scan images, shows both the

presence and location of a weld defect. The same defect is shown

on the corresponding x-ray image on the left.

|

X-ray (left) image of a crack.

Same crack shown in weld C-Scan (right) |

3D scan image of same crack |

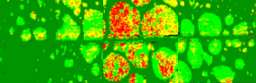

Hydrogen Induced

Cracking (HIC) flaw image. |

|