Automated Ultrasonic (UT)

Tube Corrosion Mapping

Envirocoustics

provides complete services for tube inspection of heat exchangers, boilers

and coolers. Apart from the EC and RFT methods Envirocoustics also

provides automated ultrasonic inspections.

Envirocoustics

provides complete services for tube inspection of heat exchangers, boilers

and coolers. Apart from the EC and RFT methods Envirocoustics also

provides automated ultrasonic inspections.

With the use of

completely automated UT systems, designed for rapid measurements, C-Scan

type displays are provided from small or medium diameter pipes.

A

specially retrofitted probe is inserted inside the tube, together with

water supply (as coupling material). The ultrasound is emitted vertical

(for corrosion inspection), or at an angle (from 45° to 70°, for the

detection of imperfections as microcracks).

(Download

Brochure,

209Kb)

UT probe for tube

inspection

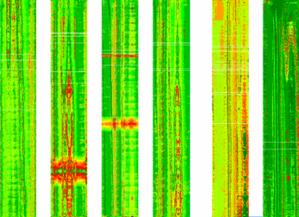

Tube mapping (in red

are the areas with reduced thickness)

All

measurements acquired are recorded and filed inside the system, separately

for each tube. The final report contains analyzed data in colored maps or

in Excel worksheets. The report contains also the highest, the lowest and

the average thickness values for each tube wall.

Advantages

of the method:

Advantages

of the method:

-

Inspection speed

up to 100mm per second, depending on the desirable resolution.

-

The probe for data

recording is inserted completely automated with a 300mm per second speed

depending on the required measurement precision.

-

Complete 2 or 3

axes recording (C-Scan and B-Scan) with capability to export the data on

Excel worksheet for further analysis.

-

Inspects tubes

with diameters from 12mm up to 76mm.

-

Thickness and

corrosion mapping and/or inspection for other types of imperfections.

Envirocoustics

also provides Eddy Currents tube

inspection services.