Ultrasonic TOFD

Weld Inspection

(Download

Brochure, 209Kb)

The

use of ultrasounds for the control of welds integrity in metal

constructions has been applied in the industry for decades.

The

use of ultrasounds for the control of welds integrity in metal

constructions has been applied in the industry for decades.

In the recent past,

an effort has begun for applying automated and semi-automated ultrasound

inspection on welds, aiming at a more rapid control, repeatability and

permanent recording of the inspection (as with radiography).

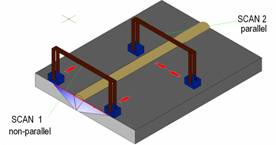

With

this context the TOFD technique was developed. The method is a variation

of the classic UT weld inspection technique and, according to that, two

special longitudinal wave UT angle probes are used that are placed either

side of the weld.

With

this context the TOFD technique was developed. The method is a variation

of the classic UT weld inspection technique and, according to that, two

special longitudinal wave UT angle probes are used that are placed either

side of the weld.

The first probe

emits a wide ultrasonic beam which scans the weld and the Heat Affected

Zone (HAZ) and the second probe receives the part of the beam that is

reflected and the signals from the diffracted waves at the edges of

discontinuities found inside the ultrasound beam.

The

discontinuity detection is based on the arrival times of the signals at

the receiver and not on the intensity of these signals and is independent

of their orientation.

The

discontinuity detection is based on the arrival times of the signals at

the receiver and not on the intensity of these signals and is independent

of their orientation.

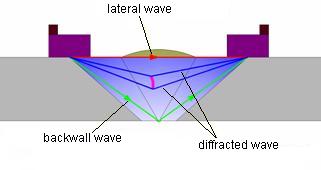

The results are

displayed in a D-Scan image (see picture) where the limits of the weld are

specified by the direct surface wave between transmitter and receiver

(upper part of the weld) and the reflected wave (lower part of the weld).

The signals from the discontinuities are found in-between these two waves.

Advantages of

the method:

-

Weld inspection

with usually one scan only.

-

No interruption of

the operation of the inspected object needed.

-

Permanent record

of the inspection data.

-

Inspection

repeatability. Suitable method for monitoring the propagation of

discontinuities.

-

The length, the

depth and the height of the discontinuity are recorded in only one scan.

-

Ideal for the

detection of cracks on the interface between wall and internal cladding.

-

No protection

against radiation required, neither interruption of other peoples work.

-

Continuous control

of probe-surface contact through the back wall echo signals and the

surface wave.

The inspection is

made according the international standards ASTM 2373 and BS 7706.

Envirocoustics

also provides

manual UT and

Eddy Currents welds inspection services.