|

Magna - Mike 8500 Precision Thickness Gage

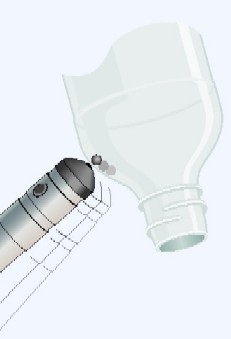

The

Magna-Mike Model 8500 is a handheld, easy-to-use thickness gage that uses

a magnetic method to make fast, accurate and repeatable measurements of

nonferrous materials. Measurements are made when a magnetic probe is held

on one side of the test material and a small steel target ball is placed

on the opposite side. The probe’s Hall Effect sensor measures the distance

between the probe tip and ball, resulting in a digital thickness reading. The

Magna-Mike Model 8500 is a handheld, easy-to-use thickness gage that uses

a magnetic method to make fast, accurate and repeatable measurements of

nonferrous materials. Measurements are made when a magnetic probe is held

on one side of the test material and a small steel target ball is placed

on the opposite side. The probe’s Hall Effect sensor measures the distance

between the probe tip and ball, resulting in a digital thickness reading.

Download pdf Brochure

(245 kb)

FEATURES & BENEFITS

-

Minimum Mode continually displays the

lowest thickness readings

-

Handheld and lightweight (2.1 lb / 0.95

kg)

-

Extensive file-based datalogger with

RS-232 serial communication port

-

Few keys for simple operation

-

Backlit liquid crystal display with large

numerals

The

Magna-Mike 8500 is the ideal instrument for measuring difficult shapes and

sizes. Nondestructive measurement

capabilities allow for pinpoint thickness readings in tight corners and

grooves down to a radius of 1/32 in (0.79 mm). The display simultaneously

shows the thickness measurement and the minimum measurement reading. The

Magna-Mike is considered the industry standard in plastic packaging, but

other proven applications include glass containers, composites and

non-ferrous metals. The

Magna-Mike 8500 is the ideal instrument for measuring difficult shapes and

sizes. Nondestructive measurement

capabilities allow for pinpoint thickness readings in tight corners and

grooves down to a radius of 1/32 in (0.79 mm). The display simultaneously

shows the thickness measurement and the minimum measurement reading. The

Magna-Mike is considered the industry standard in plastic packaging, but

other proven applications include glass containers, composites and

non-ferrous metals.

Benefits

-

Fast thickness measurements: scan rate up

to 16 measurements per second

-

Finds minimum thickness in tight corners

-

Easily measures the center of large parts

-

Accuracy of ±1 percent is not dependent on

the shape or internal properties of the test material

-

Internal datalogger stores as many as

95,000 thickness readings

Specifications

-

Minimum mode: Rapidly locates and displays

minimum thickness measurement

-

Resolution: 0.001 or 0.0001 in (0.01 or

0.001 mm)

-

Display: Liquid crystal display with

electroluminescent backlight and adjustable contrast; can display active

reading, minimum reading, alarm status and data file information

simultaneously

-

Datalogger: Stores, recalls, clears and

transmits as many as 95,000 thickness readings with 16-character

alphanumeric identification codes, and files

-

On-board reports: Minimum, maximum, SD,

mean, median and file comparison

-

Calibration: Two-point standard

calibration and as many as eight reference points

-

Differential mode: Displays difference

between actual reading and preset reference value

-

Alarm mode: Programmable high-low alarm

setpoints with audible and visual indicators

-

Line power: 100/120/220/240 VAC, 48-62 Hz

-

Battery: Rechargeable NiCad battery; duty

cycle is 8 to 16 hours depending on backlight usage; recharge time is

two hours

-

Metric/English units: Select between

inches and millimeters

-

Languages: Select between English, French,

German and Spanish

-

Operating temperature: 32 to 122 °F (0 to

50 °C)

-

Size: 9.375 by 5.45 by 1.5 in (238 by 138

by 38 mm)

-

NIST calibration certificate included

STANDARD FEATURES

-

Standard probe

-

Probe stand

-

Probe cable

-

User manual

-

Pocket reference card

-

NiCad rechargeable battery

-

External power supply/charger

-

Target ball and calibration kit including

target ball set (1/16, 1/8 and 3/16 in diameter) and calibration

standards 0.010 in / 0.25 mm, 0.040 in / 1 mm and 0.160 in / 4 mm (for

larger measurements, see optional accessories)

OPTIONAL ACCESSORIES

-

Adjustable gage stand

-

RS-232 I/O cable, 9 pin female

-

RS-232 I/O cable, 25 pin female

-

Interface program to capture data in DOS

-

Remote footswitch with two-pin Lemo

connector

-

0.020 in (0.5 mm) calibration standard

-

0.080 in (2 mm) calibration standard

-

0.240 in (6 mm) calibration standard for

applications over 0.160 in (4 mm) thick

-

NIST-traced calibration standards (set of

six)

-

Rechargeable battery

-

Spare probe cable

-

Coiled 12 ft (4 m) probe cable

-

Probe with second function button for

large test specimens

-

Probe with extended range capability to

0.400 in (10 mm)

-

Coiled 12 ft (4 m) probe cable

-

Straight 3 ft (1 m) probe cable

-

Thermal serial printer with cable and

paper

-

V-notch fixture for probe

|