37DL PLUS Ultrasonic Thickness Gage

The

new 37DL PLUS gage is an advanced nondestructive ultrasonic thickness gage

that combines powerful measurement features with sophisticated data

acquisition and output capabilities for applications involving pipes,

tanks and other metal structures subject to internal corrosion or erosion.

The

new 37DL PLUS gage is an advanced nondestructive ultrasonic thickness gage

that combines powerful measurement features with sophisticated data

acquisition and output capabilities for applications involving pipes,

tanks and other metal structures subject to internal corrosion or erosion.

Thru-Coat technology

measures and displays the thickness of the metal part and its coating

using a single backwall echo. The temperature compensation feature adjusts

the material velocity for changes in material temperature. The optional

Oxide/Scale feature measures and displays the thickness of the steel and

the oxide or scale buildup. Average/Min mode saves the average or minimum

of several successive thickness measurements.

The A-Scan display is

brighter with better contrast and visibility. Uses a large variety of dual

element and single element contact, delay line and immersion transducers.

Uses

EMAT transducers for no-couplant steel thickness measurements on

oxide scaled surfaces. The file-based alphanumeric datalogger can use

longer file names (32 characters) and identification numbers (20

characters). Every thickness reading on a stored B-Scan can now be

reviewed on the WIN37DL PLUS interface program and on the gage. Select to

view (Min/Max, Alarm or A-Scan) flags for grid points. Grid files can be

expanded by adding rows or columns or by changing the incrementing

direction.

Download pdf Brochure

(243 kb)

Transducers

The 37DL PLUS gage can be

used with a large variety of dual element and single element transducers.

Our full line of dual element transducers features automatic probe

recognition to provide maximum gage performance for each transducer. The

37DL PLUS can also use

EMAT transducers

for couplant-free measurements on oxide scale applications. The 37DL PLUS

is also compatible with our complete line of Microscan single element

direct contact, delay line and immersion transducers ranging in frequency

from 2 to 30 MHz, and recalls 16 default and 10 custom Microscan

transducer setups from memory automatically. As a result, the gage can be

used for non-corrosion applications involving materials such as plastic,

fiberglass, composites, rubber, castings and glass.

|

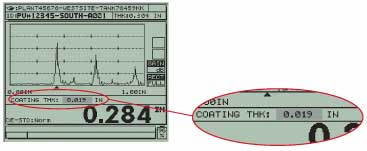

Thru-Coat Technology

This innovative feature

uses a single backwall echo to measure true metal thickness. The 37DL PLUS

can display both metal and coating thickness, each adjusted for their

correct material sound velocity. The gage can be set to display only the

true metal thickness. There is no need to remove the paint or coating from

the surface. Thru-Coat measurements use the new D7906-SM and D7908 dual

element transducers.

|

The

37DL PLUS automatically calculates and displays both the coating thickness

(0.019 in) and the material thickness (0.284 in) with a single backwall

echo

|

|

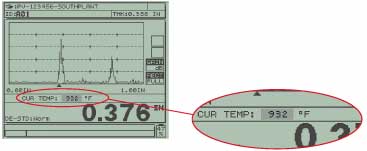

Temperature Compensation

Variations in material

temperature cause changes in sound velocity that may affect the accuracy

of the thickness measurement. The Temperature Compensation feature allows

you to enter the calibrated (normal) temperature, and also manually or

automatically enter the current (high) temperature of the measurement

points. The 37DL PLUS displays the temperature-corrected thickness, which

can be saved to the internal datalogger.

|

The

thickness reading of 0.376 in is compensated for the change in material

sound velocity due to the temperature difference between the calibrated

temperature and the material temperature (932 °F)

|

|

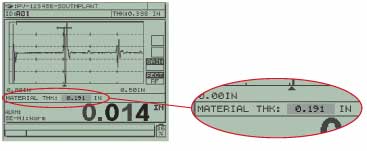

Optional Oxide/Scale Measurement

This new option uses

advanced algorithms to measure the thickness of oxide and scale buildup on

the inside of boiler tubes. Knowing the thickness of the oxide and scale

helps predict tube life. The gage simultaneously displays the metal

thickness of the boiler tube and the thickness of the oxide layer.

|

The

37DL PLUS displays the total thickness (0.191 in) and scale thickness

(0.014 in) simultaneously

|

|

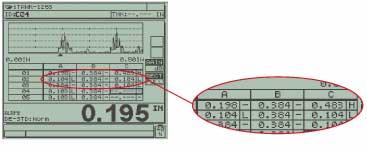

DB Grid View

With the improved Grid View

feature, you can view a Min/Max, Alarm or A-Scan flag along with each grid

point, so you can scan through a file and quickly locate Min/Max, Alarm or

A-Scan locations.

|

Flags

clearly indicate (H)High Alarm and (L)Low Alarm thickness measurements

|